The key is not to prioritize what is on your schedule, but to schedule your priorities

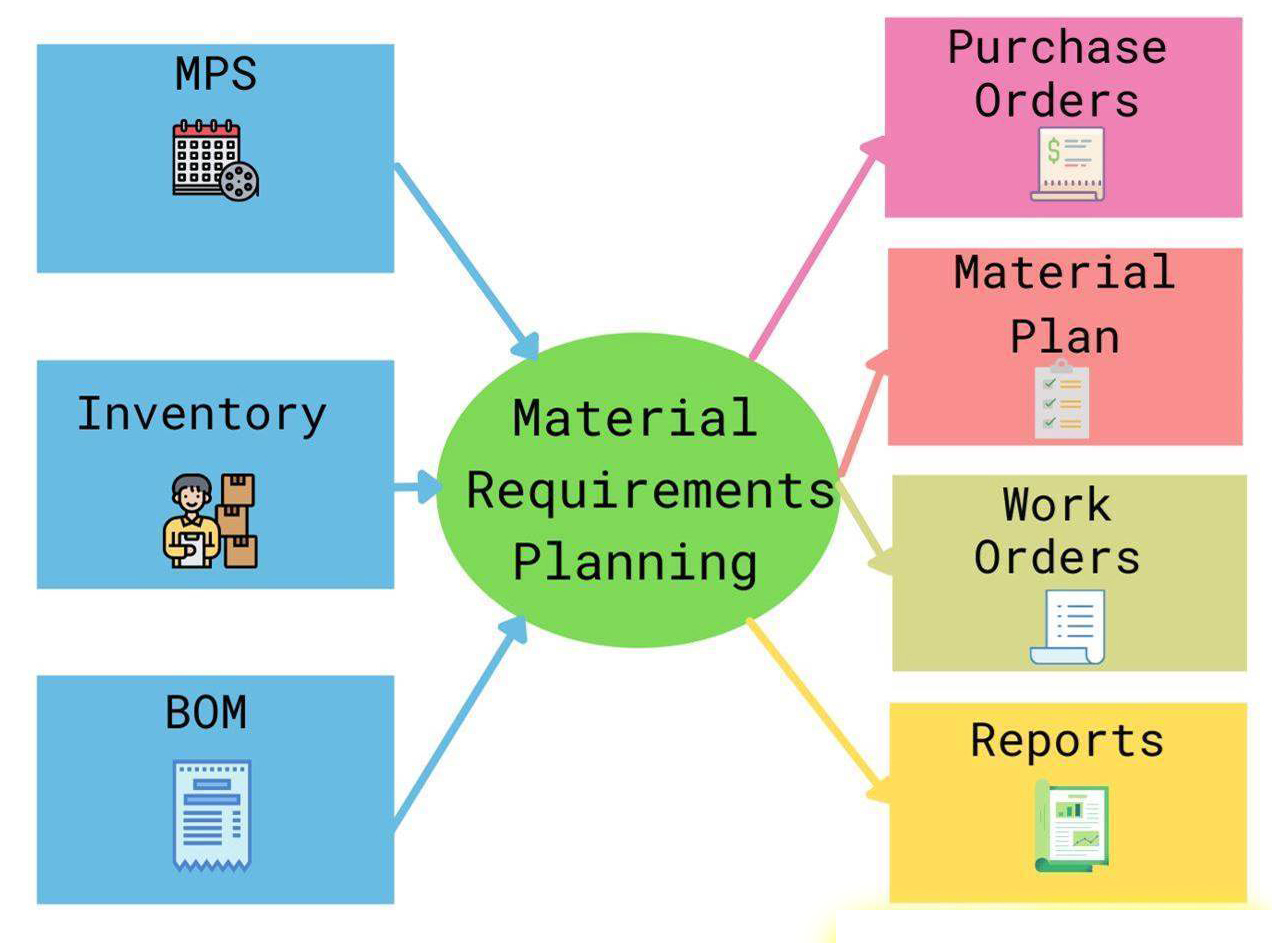

The Material Requirements Planning (MRP) Module can help you eliminate Purchasing and Scheduling problems. It is designed to simplify and speed up the work processes of Purchasing, Inventory, and Production Managers, enabling them to plan more effectively.

MRP helps you quickly consider and evaluate your demand, based on your open Sales Orders and Sales Projections. It also focuses in maintaining the lowest possible level of Inventory and planning Manufacturing activities, Delivery Schedules, and Purchasing activities.

The main objective of Material Requirement Planning is to ensure the availability of Materials, Components, and Products for Planned Production and for Customer Delivery.

It also focuses in maintaining the lowest possible level of Inventory and planning Manufacturing activities, Delivery Schedules, and Purchasing activities.

Material Requirement Planning includes the process of making a Production Plan, MRP & then generating Purchase Requisition.

KAD ERP MRP MODULE has the feasibility to analyze the requirement in different ways like ignoring the available stock, ignoring stock of finished good items, considering pending PO quantity as stock, etc. MRP MODULE allows us to analyze completely all the requirements and generate Purchase Requisition against it.

The important components of MRP modules

- MRP against so

- MRP against min & max

- MRP against work order

- MRP against maximum movement

Our Modules

Like to boost your business?

Let’s get in touch with us right now!!