×

Enquiry Now

Even the best-built machine needs proper preventive maintenance to remain productive & reach their maximum working life.

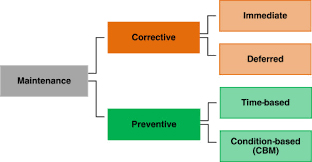

Machines and equipment are core needs for every industry for it to be successful running. These machines and equipment need to be maintained in the proper time for their long life. The plant maintenance module involves maintaining the machines and equipment of a single facility or multiple facilities depending on the production of the industry. The module also schedules maintenance, calculates downtime, and maintains calendars for tasks. KAD ERP plant maintenance module is an absolute solution for the industry. The module helps in maintaining the workflow, preventive maintenance, asset tracking, tracking and purchase, inspection, repair and maintenance, and reports.

- Avoid costly repairs resulting from over-used or misused equipment

- Eliminate disruptions to the production schedule due to last-minute and emergency repairs

- Improve equipment reliability and longevity

- Improve visibility of all costs associated with work centre MRO downtime

- Improve accuracy of maintenance cost tracking and reporting

Extensive functionality

- Single window system for capturing work done against preventive maintenance, defect log, work requisitions, breakdown and shutdowns.

- Capturing of details of Jobs done, Spares consumed, Manpower consumed, Time spent, cost incurred, etc.

- Structured Maintenance logs- capturing Symptoms, Cause, Fault/Failure and Remark etc. This information helps in the effective analysis of failures and acts as decision support.

Maintenance Work done

The important components of maintenance modules

- Machine master

- Preventive maintenance schedule for machine

- Machine calibration report

- Maintince call management

- Maintenance log report

Our Modules

Like to boost your business?

Let’s get in touch with us right now!!

Have new project ?

Contact us